Plastic is one of the best suited materials for CO2 laser cutting. Polymer laser cutting is a very efficient and effective industrial process. Among all the plastic polymers that can be processed by CO2 laser, polyethylene is one of the first in terms of frequency of use. Polypropylene has an excellent laser energy absorption capacity which makes it suitable for all types of applications ranging from drilling to welding.

Polypropylene: characteristics and uses

Polypropylene is a thermoplastic polymer obtained from the polymerization of propylene.Its main feature is that the molecules making up the polymer can be arranged in an ordered or random way. In the first case, polypropylene takes on the characteristics of an isotactic polymer.

This configuration is the most commonly used commercially since it gives the material excellent chemical, physical and mechanical characteristics.

Polypropylene has a high heat resistance (greater than polyethylene), good elasticity, rigidity and the ability to absorb shocks without breaking. It also has a low density, (which makes it light), a high insulating power and good resistance to oxidizing and chemical agents.

Finally, polypropylene can be processed in a variety of forms: injection molding, thermoforming, extrusion for the creation of textile fibers.

Given these characteristics, polypropylene has found a myriad of applications in every field. One can argue that there is no industrial sector that does not make use of polypropylene in some shape or form.

Here is a list of the objects that are most often made with this material:

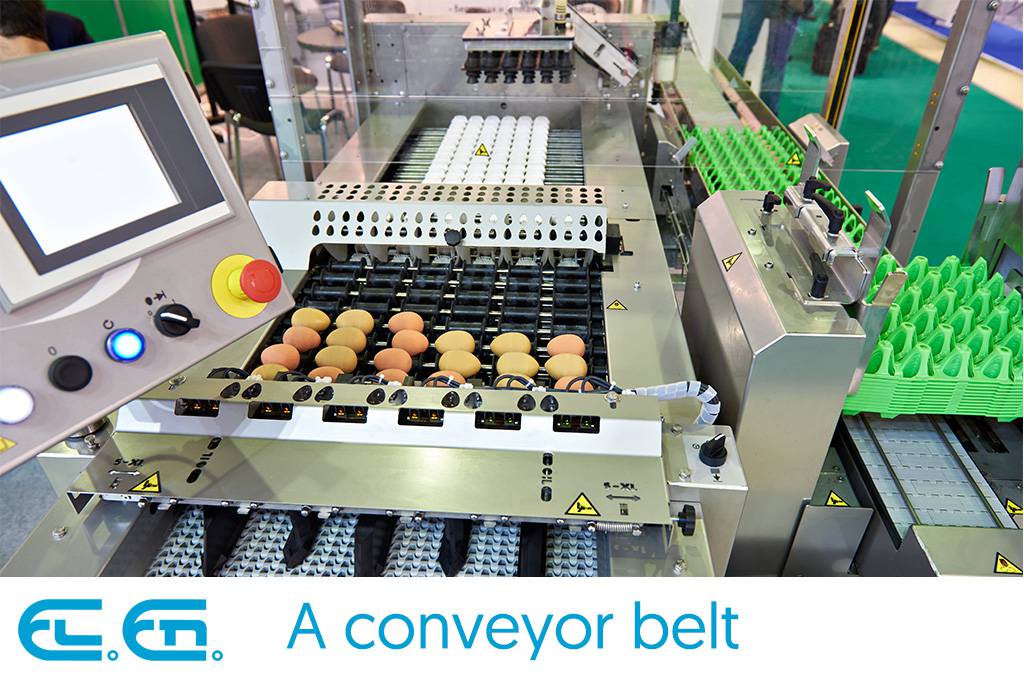

- Packaging, labels and containers

- Kitchen items such as dishes and food containers

- Sportswear

- Components for automobiles

- Bags,

- Sanitary objects

- Electronic object components

Can you cut polypropylene with laser?

Yes, of course. Polypropylene laser cutting is a very efficient process since this polymer absorbs the infrared wavelength of CO2 laser very efficiently. With laser, making cuts or drilling holes on polypropylene is very easy.

On a macroscopic level, laser works as a cutting blade. The cut has a smooth and well-finished straight edge with no presence of burns or charring. Burr formation or cutting irregularities due to the presence of residues are also very limited. The high energies produced by laser not only melt the plastic, but makes it evaporate by sublimation.

The quality of the cut is directly influenced by the laser power, the cutting speed and the thickness of the material. In general, a medium-power CO2 laser source is sufficient to perform most of the processes needed in polypropylene applications.

Furthermore, the quality level is also influenced by the wavelength used. For this type of material our team of El.EN engineers have devised a specific laser source: BLADE RF333P.

This tool is very well suited to label cutting applications which use the kiss cutting process. A fundamental characteristic of this process is the variation in wavelength absorption related to the type of plastic film used.

In addition to simple cutting, polypropylene also lends itself well to laser kiss cutting operations, a process used mostly in adhesive production processes. Drilling polypropylene is also a suitable application, especially useful in the fabrication of plastic bags for modified atmosphere packaging.

Implementing a laser system for polypropylene cutting

The process of laser cutting polypropylene has many advantages: it allows you to perform complex, precision machining with great speed. It is also a very flexible system, which lends itself to numerous applications.

In addition to cutting, polypropylene responds very well to other laser processes, especially drilling (perforation), marking and engraving, welding. The same laser source can carry out all these processes.

If you work with polypropylene and would like to shift to CO2 laser technology, contact us. We would be happy to help you find the most suitable laser solution for your needs.