Let’s continue exploring the applications of CO2 lasers. In this article we will be talking about acrylic and CO2 laser.

Acrylic, also known as PMMA or plexiglas is one of the plastic materials that can be laser processed with success. In particular, CO2 laser is the right to do the job.

What is acrylic and why it is so successful

Acylic was discovered in the 1920s. However, the material only really gained ground only after WWII as a cheap and effective replacement to glass. Easy to manufacture and process, rugged and flexible, acrylic has imposed itself as a successful material for a wide range of uses.

CO2 laser and acrylic

Acrylic is also known as PMMA. This acronym stands for Poly Methyl Methacrylate and refers to its chemical formula which includes atoms of carbon. For this reason acrylic materials responds very well to the wavelength of CO2 laser, which is 10.6 micrometers. At this wavelength, acrylic is opaque to CO2 laser, which is therefore absorbed very well by the material. This feature, coupled with low thermal conductivity and a relatively low sublimation point (300 °C), allows acrylic processing to be done quickly and easily. As a matter of fact, the fabrication of acrylic materis is one of the applications in which CO2 lasers give the best results.

Laser cutting acrylic

The main laser processing technique for acrylic is probably laser cutting. As se we have seen, the interaction between the laser and acrylic is very efficient. That means that when a CO2 lasers interacts with an acylic surface, the latter absorbs a large part of the energy conveyed by the laser, which is focused then on a tiny spot.

High energy on a very small surface means instantly vaporizing the material and as a result we obtain the cut. This process is called by sublimation of the material. Sublimation causes the material to evaporate and therefore does not create residues, making laser cutting an extremely clean process.

The end results of this process is extreme precision and quality. The cut has clean and smooth straight edges that don’t require further finishing.

The acrylic laser cutting process is also incredibly fast. Speed ​​is related to the thickness of the material and the power of the laser source. But whatever the thickness, the processing speed will be significantly higher than the mechanical cutting methods, even if it is a CNC method.

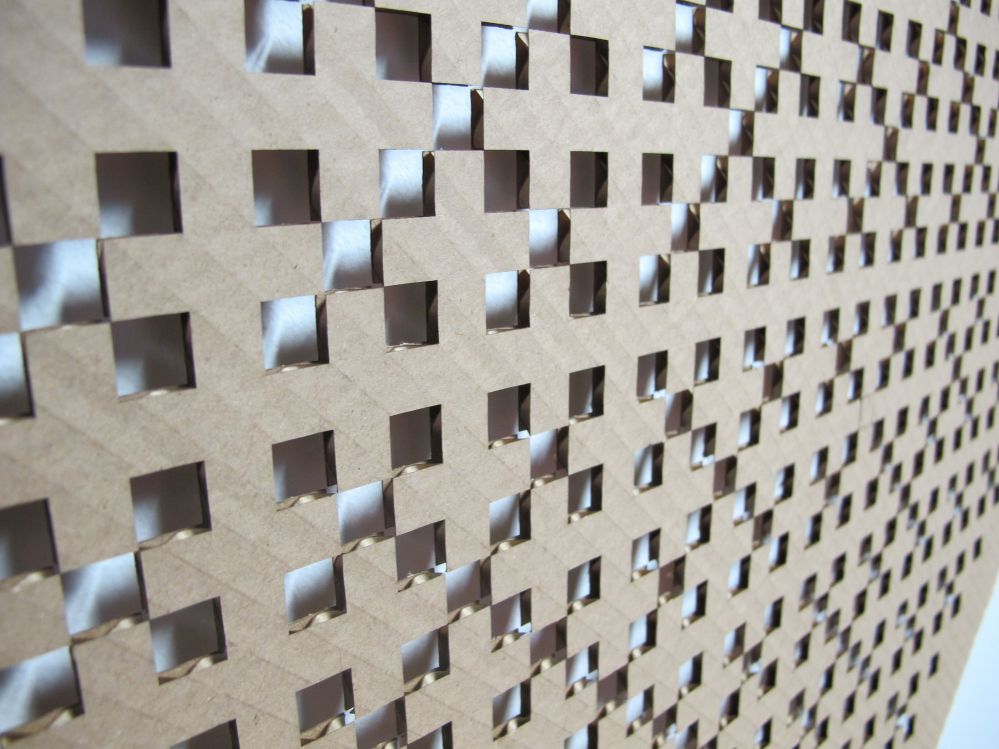

The possibilities of laser machining are endless and, ultimately, only limited by the designer’s imagination.

Do you need a laser cutting system?

At El.En. we have a long experience in producing laser systems for the fabrication of acrylic. We can design complete laser system or integrate our CO2 laser in existing laser. For whatever request or question you might have just contact us!