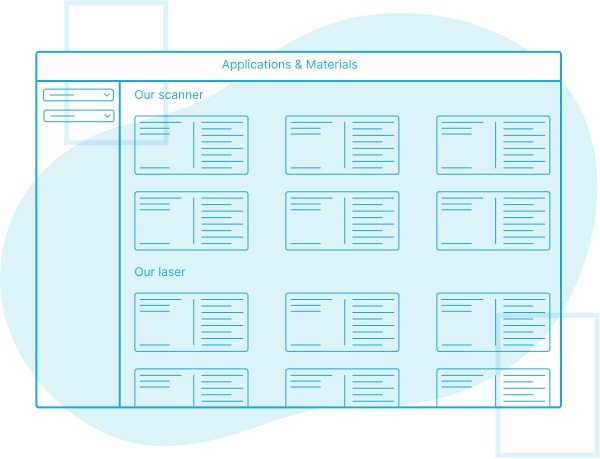

Select Application

Select an application or a material to see all related products.

Select a filter from the left list to see all related products.

Rated power (W)

600

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

500

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

400

Wavelength (μm)

9.3 ± 0.1

Rated power (W)

400

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

1500

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

1200

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

850

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

850

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

750

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

550

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

320 ÷ 350

Wavelength (μm)

10.2 ± 0.2

Rated power (W)

320 ÷ 350

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

300

Wavelength (μm)

10.2 ± 0.2

Rated power (W)

300

Wavelength (μm)

9.3 ± 0.2

Rated power (W)

300

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

150

Wavelength (μm)

10.6 ± 0.4

Rated power (W)

80

Wavelength (μm)

10.6 ± 0.4

Working area (mm)

770x390

Working area (mm)

from 500x500mm to 1800x1800mm

Working area (mm)

from 150x150mm to 800x800mm

Working area (mm)

from 300x300mm to 600x600mm

Working area (mm)

from 50x50mm to 300x300mm

Working area (mm)

from 50x50mm to 300x300mm

Materials

Abrasive materials

How would you cut sandpaper without wearing out or blunting the cutting tool? It would be hard without using a blade as hard as diamond. But you can use a laser cutter. Being a non contact process, a laser cutter is a precise and sharp tool for cutting abrasive materials. Abrasive materials are within the broad array of non-metals that can be successfully processed by El.En.'s CO₂ laser sources. You can cut your sheets in different shapes, based on the requests of your customers. All kinds of shapes can be obtained without risking any material deformation or tool wear. But what's interesting, is also you being able to cut, together with the abrasive material, its backing substrate, be it paper, foam, rubber and the like. Explore which CO₂ laser sources are the most suitable for your production needs.

Cardboard & Corrugated

For some industries, the container is as important as the content. Cutting or marking cardboard sheets with CO₂ laser allows the creation of attractive packaging that can help better sell products. Whether your packaging is designed to showcase ripe blackberries or protect precious crystal glasses, El.En. laser sources will streamline your process. Laser cardboard processing gives you all the advantages of digital finishing: Cutting intricate designs with smooth edges and perfectly square joints, high-speed processing, accuracy and flexibility even on tight tolerances. No hard-tooling is required: Avoid the costs of designing tools, forget tool wear and periodic tooling substitution. Laser processing is no-contact and that's why it can be so fast and flexible and cost-effective.

Ceramic & Alumina

Ceramic can be effectively cut and decorated with CO₂ laser sources. Owing to its high absorptivity of the 10.6 micrometers radiation, alumina (Al2O3) is the variety of ceramic that benefits the most from digital laser processing. Cutting of alumina is achieved by high-power laser pulses that vaporize the surface and produce perfect cuts. CO₂ laser can also be used for the decoration of tiles and other ceramic surfaces. With laser engraving, items are decorated with extreme precision, and according to the power of the CO₂ laser produced by El.En., contrasting and shading is achievable as well. These features make El.En.'s laser sources the perfect choice for applications such as cutting and decoration of ceramic and alumina.

Fabrics & Denim

Coupled with a scanning head, a CO₂ laser source can easily process fabric, be it synthetic or natural. Because of its low thermal conductivity and high energetic absorptivity, fabric absorbs great part of the energy it receives, and thus it can easily be cut or marked even by low-power CO₂ laser sources. No moving parts or hard-tooling are involved: The laser beam is steered onto the surface by the mirrors of a scanning head, following a specific, computer-driven path. Depending on the speed of the scanning head, the same laser source can either mark or cut. Less waste, less dust, clean edges are only a few of the advantages you will gain in using El.En.’s technology. Find out which of El.En.'s laser devices can best serve the needs of your industry!

Food

CO₂ lasers are a good choice for organic materials processing, because, like all carbon based materials, they absorb the 10.6 micrometers radiation of a CO₂ laser well. As a consequence, achieving laser organic material processing requires a very tiny amount of energy. Laser marking or bio-stimulation can be achieved in a new and cost-effective way. Through the years, El.En.'s laser sources found application all over the world in industrial processes as diverse as marking Parmesan cheese, fruit, or ham, cutting chestnuts or grafting plants.

Glass & Quartz

When it comes to marking glass, nothing is better than CO₂ laser sources. Although it is transparent to visible light, glass absorbs the infrared light emitted by a CO₂ laser sources, resulting in a higher thermal efficiency and thus in cost reducing process. El.En.’s laser technology allows engravings in a simple, precise, and most of all lasting way, without changing the properties of glass. El.En. laser CO₂ laser sources and scanning heads are currently being used by many manufacturers in the fashion and machine tool industry. Learn about El.En.'s laser devices that will streamline your production processes.

Leather

Leather laser processing is widely used in the decoration and fashion industries. Cutting out intricate shapes, drilling hundreds of micro-holes or etching the most complicated arabesque is possible with El.En.'s laser sources. Using laser on leather is an extremely efficient operation: Since leather is a high-absorptive and low-conductive material, it takes small amounts of energy to get great results with low costs. Forget strong fixturing, metal dies or slow operations: The implementation of a laser source in your system will dramatically streamline your clean leather processing operations and boost your productivity rate!

Laser source technology offers several advantages:

• exclusive and incomparable decorative effects;

• low operational costs;

• inexistent environmental impact;

• work safety.

Marble & Stone

Marble, granite and polished natural stones can be successfully processed with CO₂ laser. Coupled with an El.En.'s laser scanner, El.En.'s CO₂ laser sources mark marble slabs at an exceptional level of detail. Laser marble processing works through ablation of a thin layer of material from the surface. Being a non-contact process, this technique is much faster than any mechanical method. No tool wear, no need of cleaning, no strong fixturing: Laser marking of marble slabs at this level of detail has never been so straightforward.

Metals

CO₂ laser can also be used on metals and is particularly suitable for cleaning and paint stripping. Laser cleaning is used at industrial level for the maintenance of machinery, tools and products. It can be useful to remove processing residues such as grease, rubber or other carbon-based materials. Laser paint stripping is part of the laser cleaning application family, where the laser is used to remove a layer of paint from a large or small metal surface. Both laser cleaning and laser paint removal utilise the CO₂ laser's ability to selectively target only the materials that are compatible with its wavelength. Cleaning operations can therefore be carried out without the risk of accidentally damaging or abrading the surface to be cleaned.

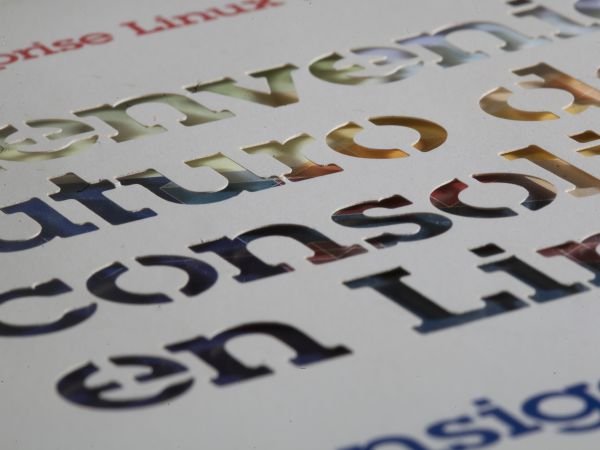

Paper / Label

Paper and cardboard respond very well to the wavelength emitted by CO₂ laser beams. That makes paper digital converting extremely efficient. Being a non-contact process, laser finishing avoids the risk of deformation or distortion of the base material, always ensuring clean cuts and square edges, even with the most intricate designs. For those reasons, cutting and marking are the obvious applications of laser paper processing. Owing to their accuracy, El.En.'s CO₂ laser sources are also used in applications such as laser kiss cutting and laser micro-perforation, especially in the packaging and decorating.

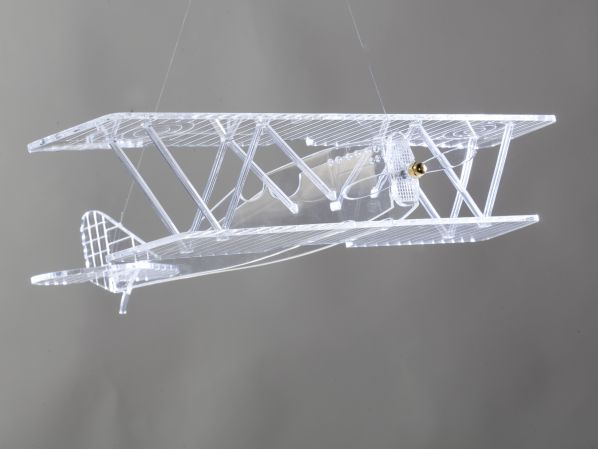

Plastic

Many types of plastic can be cut, drilled or marked by a CO₂ laser beam. Laser plastic processing gives you many advantages over traditional methods. When you're looking for precision in geometry and extreme operational flexibility, on close tolerances and on a micro-scale, any of the wavelengths emitted by a CO₂ laser beam can do the job. The final parts won't require refinement, avoiding any waste of base material and ensuring the highest level of accuracy. El.En.’s laser sources will process various types of Plexiglas: Clear, colored, textured, mirror-like or with silicate coating (methacrylate, PMMA). Acrylic fumes produced during the manufacturing will be sucked away and filtered during the process. El.En.'s CO₂ laser sources will enhance your productivity rate: Our ultimate goal is to make you produce faster and better.

Plastic film

CO₂ laser is a groundbreaking tool for plastic film processing applications. Packaging, coating, digital converting markets will all benefit from a CO₂ laser solution. Being a non-contact process, laser is perfect when you have to deal with a base material as delicate as plastic film. It is a non-contact process: You won't waste or deform the plastic film and you will get the most accurate results achievable today in manufacturing this plastic material. El.En. laser scanning heads make this process possible: They will steer the laser beam emitted by the CO₂ laser source, focusing it precisely where it is needed. By doing so, you will achieve processing such as kiss cutting, micro perforation or welding in applications such as easy opening packaging, micro-perforated films for bread and vegetables.

Rubber & Foam

Rubber and foam are ideal for laser processing. Both natural and synthetic rubber and foam can be effectively cut by CO₂ laser sources. Compared to traditional cutting techniques such as die punch, laser digital finishing ensures a high accuracy and quality of cut, even at very tight tolerances. Forget tool wear, strong fixturing or a bad quality of the cutting edges: Being a non-contact process, laser cutting produces a neat cut even at the highest processing speed. El.En.'s CO₂ laser sources can achieve cutting or marking applications at a great level of detail and within close tolerances.

Wood & Derivatives

A CO₂ laser source is an excellent choice for non-metals such as solid wood and engineered wood. Like every carbon-based material, wood absorbs a large amount of the power emitted by a CO₂ laser beam at 10.6 micrometers. That's why cutting and decorating are the mainstay of laser woodworking: Depending on the output energy, the outcome goes from simple engraving to die cutting. Compared to traditional woodworking, laser wood processing has no equals in speed and flexibility. El.En.’s laser sources and scanning heads are geared towards dealing with the tightest tolerances and the most intricate designs to let you meet the strictest requirements of quality and precision.

Many other are the uses of laser on wood: Engraving of any thickness and kind of wood, Wood-covered paper and dual-color wood, Marking on natural, semi-finished, finished and polished wood or Grooves on thick materials, especially rough or semi-finished.

The results obtained on rough wood may acquire colors ranging from dark brown to beige. Effects of simple opacification may be obtained on laminated or painted materials, according to their composition.

Processing

Laser Ablation

Laser ablation is indeed a versatile and precise technique for material removal from solid surfaces using laser energy. Laser ablation is highly precise, allowing for micron-level control over material removal. This precision is particularly advantageous in industries where selective material removal is crucial. The Minimal Heat Affected Zone (HAZ) is also a significat feature: laser ablation is a relatively low-heat process that minimizes the heat-affected zone, reducing the risk of thermal damage to the surrounding material. Materials like metals, polymers, ceramics, and composites can be laser ablated. This versatility makes it suitable for a broad spectrum of applications across different industries. In addition to material removal, laser ablation is widely used for surface cleaning. It can efficiently remove contaminants, oxides, or unwanted layers from surfaces, ensuring a clean substrate for subsequent processes.

Laser Cleaning

Stripping large surfaces is a complex and expensive process. It normally requires the use of chemicals, considerable water and many hours of work. An environmentally friendly and flexible alternative to traditional paint stripping is laser stripping. Laser paint removal involves using laser to remove a layer of paint from the metal substrate on which it is applied. The main advantage is that the beam acts selectively on the paint without touching the metal underneath. The process is ideal for removing paint in a specific area, for example when particular points on the surface, covered with paint in a previous passage, need to be stripped for subsequent functionalization. Of all the paint stripping processes available, laser stripping is the most environmentally friendly: The beam instantly vaporizes the paint without producing any waste or residue. If you are looking for a precise, selective process to perfectly strip irregular or easily damaged surfaces, laser is the solution for you.

Laser Cutting

CO₂ lasers are tools that offer outstanding power and flexibility in laser material cutting applications. Laser cutting is a thermal process in which a laser, assisted by a gas, heats up the material, resulting in the alteration of its state. Laser material cutting advantages include great versatility regarding cutting speed, geometry, precision and accuracy of the cut. Plus, no further processing is required: The part you'll get will be perfectly finished. The typical 10.6 micrometers wavelength of CO₂ laser sources is readily absorbed by a wide range of materials. Metals, ceramic, wood, paper, glass, fabric, composites: a high-power CO₂ laser source will slice them like a knife. Owing to their beam quality and energetic efficiency, El.En's RF CO₂ laser sources are perfect for all those industries where achieving precision cutting is a strategic asset: Automotive, packaging, machine tool, lcd processing and others.

Laser Drilling

Imagine the possibility of making thousands of holes of any caliber in a short time. And without producing any chips and at exactly defined locations. That's exactly what a CO₂ laser source can do. Laser drilling is one of the most diffused laser applications, along with its sibling laser microperforation. Basically, the laser beam striking the surface of a plastic, metal or ceramic material, makes the base material evaporate. The holes resulting from this operation will have neat edges and won't need further processing operations. Furthermore, for drilling applications you can use the same laser sources you would use for cutting operations! El.En.'s laser sources have been engineered to work on metals, ceramic and plastic materials in machine tool, packaging, food, printing and decoration industries.

Laser Kiss-Cutting

Laser kiss cutting is a special cutting technique. It is very useful in the paper converting and label production industries: Laser kiss cutting aims at cutting only the top layer of a two-layered sheet instead of cutting through a sheet of paper, as in traditional laser cutting. The production of sticky labels is one of the main fields of application of this processing technique. The advantages of laser kiss cutting are remarkable: Since it is a non-contact process, there won't be any die or blade getting glued to the adhesive layer, avoiding the costs of tool cleaning. Futhermore, laser kiss cutting applications do not require special equipment: A single CO₂ laser source can achieve both laser kiss cut and laser cut through processing. Laser kiss cut is great to be employed in the paper and label industries, where it can be easily integrated into the printing process, but is also perfect for the coating and film industries.

Laser Marking

High powered CO₂ lasers sources have become the standard tool for marking and engraving applications. Laser marking is a thermal process, which works through the ablation of a thin layer of the base material produced by a pulsed laser beam. All this results in a series of shallow pits on the surface that make the mark visible. When the marks made by laser are deeper we refer to laser engraving. Typically, lasers are used to mark bar codes, part codes and identification numbers, company logos and various graphics. Depending on the laser parameters, almost all types of materials can be successfully marked. Compared to traditional techniques laser marking offers high reliability, high speed, real time operability and low operating costs. El.En.'s sealed RF excited CO₂ laser sources have been engineered to achieve top grade results in marking applications: High laser beam quality, wide power ranges, high repetition rate and versatility. Hence, they are the perfect choice for applications in the packaging and electronic industries.

Laser Micro Perforation

Laser microperforation or laser microdrilling is the process of laser drilling micro holes on materials such as plastic films, paper and fabric. It is a subset of laser drilling processing techniques. Compared to mechanical micro perforation, laser offers speed, flexibility, resolution and accuracy. El.En.'s CO₂ laser sources operated in pulsed mode will pulse at a maximum frequency of 100 Khz to get perfectly round holes, with no debris or signs of recast. Owing to those characteristics, El.En.'s CO₂ laser sources are widely used in the food packaging industry, to create containers that will guarantee the quality of the food they store. Other applications are in the automotive industry to drill micro holes in tissues and in the fashion industry to make decorations based on micro-perforation.

Laser Welding

Like traditional welding processes, laser welding aims to join two parts together. However, a CO₂ laser will do it better, faster and with greater accuracy. CO₂ lasers are succesfully used as a heat source for welding operations. The laser beam heats the edges of two parts to be processed: The heat melts the material, causing the two parts to fuse where they are contiguous. Its main field of applications is laser welding of plastic polymers. This processing technique can be used, for instance, to hermetically seal plastic bags, or to join together parts that are difficult to join with traditional welding tehcniques due to their layout. This makes laser welding excellent in all those applications where extreme precision is required even at micro-scales. But how is it performed? El.En.'s RF CO₂ laser sources coupled with an AZSCAN (for CO₂ laser) laser scan head, have all the key features to do the job. Beam quality and size, power range and components have been engineered to allow you to achieve great polymer welding results in the automotive, lcd and packaging industries.