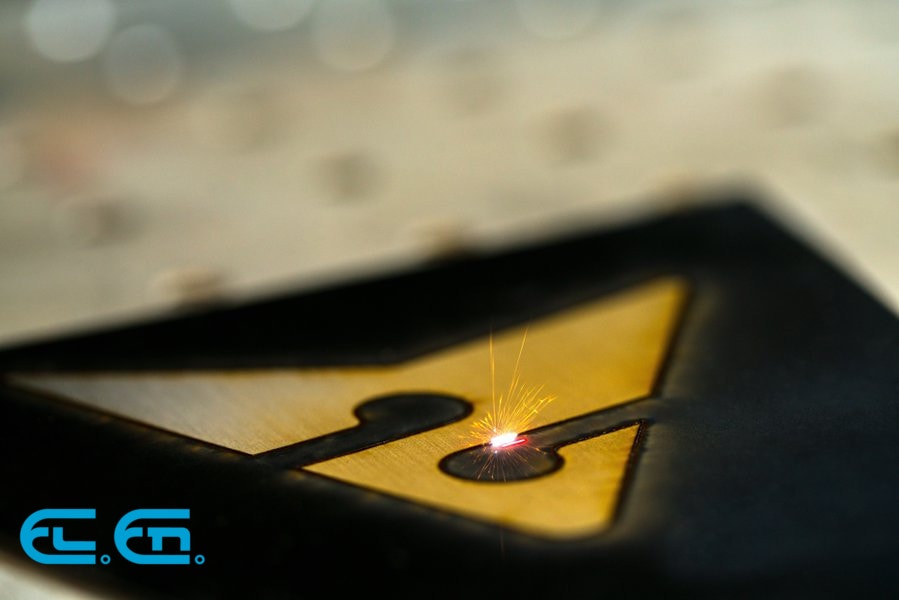

In recent decades, lasers have become a widely used processing tool. Its role as a production tool is increasingly established, both in traditional applications such as laser cutting, laser welding or laser marking, and in more advanced ones such as laser paint removal, laser surface treatment or laser microperforation.

The success of this tool is due to the advantages it offers in terms of process flexibility. The same laser source can be used to perform different processes such as cutting and marking on different materials such as plastic and wood, even within the same operating cycle.

This great flexibility translates into process complexity. In general the working mechanism of the laser is very simple. A laser is a light source capable of concentrating a very high energy density, so much so that it can be used as a heat source. In practice yet, the interaction between the laser and the material is influenced by numerous factors that make it very complex.

Conceptually, cutting, drilling, engraving and marking share the same processing mechanism: laser energy is used to create chemical and physical transformations in the material. These transformations can range from the simple colouring of the material, as is the case with laser marking, to the complete removal of the material by sublimation as is the case with laser cutting. In order to switch from one process to another, it is sufficient to modify the laser parameters using the appropriate control software.

For this reason, each application must be studied according to the characteristics, of the laser, of the process and of the material.

In this article we will analyse the main parameters that come into play in laser processing, with particular reference to the CO2 laser.

Laser-related parameters

Unlike traditional production tools, laser technology has a wide range of configuration options. Each parameter affects the end result of the process and must therefore be configured appropriately according to the desired result on the material.

The laser parameters to pay attention to are:

- laser source power

- beam spatial mode

- beam temporal mode

- laser wavelength

- beam polarisation

Laser source power

The power of the laser source is a very important parameter. It regulates the laser’s processing speed and the depth of the engraving. The more powerful the laser, the greater the amount of processed material in the same amount of time. Furthermore, the more powerful the laser, the thicker the material that the laser will cut can be,although, as we will see further on, this parameter depends in part on the characteristics of the material.

If you are using a low-power laser, it may not be possible to cut a material from side to side. On the other hand, a laser with a higher power than the one needed to carry out a specific process, can cut through the material, with the risk of obtaining a lower quality cut, with burnt and uneven edges due to the slag produced by the excessive power of the laser.

As a general rule, the choice of the power of a laser source should be made in excess so that the power can be lowered until the desired result is obtained.

Spatial mode of the laser beam

This parameter defines the cross-sectional profile of the laser beam. A laser beam can have several modes, i.e. it can have different profiles.

The most commonly used mode in laser cutting applications is the Gaussian mode, as it allows maximum energy density to be produced, i.e. the beam is concentrated in a very small diameter point.

In this way, it is possible to obtain cuts and engravings with very reduced dimensions, with high processing speeds and the possibility of cutting larger thicknesses.

Other spatial modes, on the other hand, allow the beam to be focused on a larger surface area, thereby achieving lower energy densities.

Time mode of the laser beam

Lasers can be used in two modes, continuous wave or pulsed mode. The continuous wave mode is the most widely used (mainly in mass production), and allows very smooth cuts and thicker materials to be cut. The pulsed mode is used for more precise work, often with a low-power laser.

Wavelength

The way different materials absorb laser radiation depends on their wavelength. While some materials absorb the wavelength of the CO2 laser very well, others require different wavelengths and therefore other types of laser.

Aluminium and copper, for example, absorb the wavelength of the CO2 laser very little and require very high powers to be cut, which reduces production efficiency. Non-metallic materials such as wood and synthetic materials such as polymer plastics, on the other hand, absorb the CO2 laser radiation perfectly. Metals such as mild steel and stainless steel can also be cut with the CO2 laser with excellent results.

Polarisation

Polarisation refers to the ability of the laser beam to radiate in only one direction. This property differentiates the laser from non-polarised light sources, which radiate in all directions.

This parameter is important insofar as it affects certain characteristics of the cut. Generally speaking, when the cutting direction and polarisation have the same orientation, very thin, sharp-edged and vertical cuts are obtained. When the direction of the cut is the opposite of the one of the polarisation, the energy absorption of the material is reduced, resulting in a reduction in the speed of machining and a wider cut with rough, irregular edges.

Material characteristics

When configuring a laser system, the characteristics of the material must be taken into account. Not all materials are laserable. Some do not absorb certain wavelengths; others produce unsatisfactory results when subjected to the laser beam.

Thermal properties and reflectivity are the parameters of a material that need to be taken into account.

Thermal properties

From the point of view of laser processability, materials can be divided into two categories, metals and non-metals. The two groups respond differently to laser radiation and therefore offer different degrees of processability.

Metals have high thermal conductivity, a higher melting point and high optical reflectivity. For this reason, laser processing is very inefficient in most cases.

Non-metals, on the other hand, absorb laser radiation very well, particularly that of the CO2 laser, and can therefore be processed very efficiently. All it takes is a small concentration of laser energy to initiate the material transformations that carry out the processing.

Reflectivity

This property is especially relevant for metals. While we can generally say that all metals have a high degree of reflectivity, it is not a fixed parameter. The reflectivity of a metal can vary as the physical properties of the metal change. For example, reflectivity decreases when a metal is heated or when shorter wavelengths are used.

The reflectivity of a metal can be limited by the use of a non-reflective film applied to the surface of the material.

The polarisation of the beam also affects the reflectivity of a material.

Process characteristics

The laser machining process can be carried out in many different ways and use different technologies.

The following features of the machining process influence the final result:

- beam travel speed

- assist gas

- nozzle shape

- stand-off distance

- focal plane position and focal length

Beam travel speed

The travel speed of the beam is crucial in determining the final processing result. The thicker the material, the slower the laser has to travel because if it is too fast, it cannot penetrate the material.

In some cases this principle can be used for a purpose, such as laser marking and engraving.

On the other hand, if the laser proceeds too slowly, the material gets too hot, increasing the heat in the affected zone, which can lead to charring and damage to the material.

The right speed is the one that achieves the best quality for the desired result, as efficiently as possible.

Gas assist

In some cutting processes, the laser emission may be accompanied by a gas jet. This technique makes it possible to improve the efficiency, speed or quality of machining.

Some of the most commonly used gases are oxygen, used to cut mild steel, nitrogen, to cut nickel alloys. Helium, argon and other inert gases and simple compressed air are also used.

The gas jet can be either coaxial to the laser beam or directed. The final decision depends on the characteristics of the desired processing.

Nozzle shape

The nozzle is the device through which the laser beam is irradiated onto the processed surface. Its configuration has an influence in determining cutting characteristics such as shape, size and edges.

Stand-off distance

This parameter is determined by the distance between the nozzle and the processed surface. The spray distance affects the gas flow. Too great a distance can cause turbulence, which creates irregularities in the cut. If, on the other hand, the nozzle is too close to the work surface, splashes of molten material can damage the laser’s focusing lens.

Focal plane e position and focal length

The laser needs to be focused on the working surface at all times. The focus point must therefore always be on the processed surface, in order to achieve maximum energy density and precision. Controlling this parameter is essential to obtain good quality and uniform processing along the entire path of the laser.

Every laser configuration is specific

In summary, it is clear that it is not possible to standardise laser applications. The processed materials, the characteristics of the process and the technical characteristics of the laser system determine the type of configuration one should use. Contact us: our experts can define a process that suits your needs!