What if producers and distributors of fruit and vegetables stop using sticky labels? It’s not phantasy but reality: with laser food labeling, labels can be written directly on the skin of a product by removing the superficial layers of the skin itself. An innovation beneficial for the environment and for the consumer. In this article we describe you this processing technique and we present you a case study where we describe how we created an automatic laser system for the labeling of apples.

First priority: reducing waste

Recent years have seen the development of a greater sensibility towards the environmental impact of the production processes. Manufacturers are trying to streamline the use of resources and materials, switching to greener ways of producing goods.

For the packaging sector this meant an overall reduction of the materials composing the packaging products: paperboard boxes, rolls of wrapping paper and plastic films are being supplanted by their biodegradable equivalents or they are simply being discarded.

Quite revealing of this trend is what happened to the most simple and traditional packaging product: labels.

CO2 laser labeling? That’s natural branding!

The phenomenon has been called “natural branding” and it especially concerns the packaging of fresh fruits and vegetables. Simply put, natural branding is to replace plain physical labels, sticked on the surface of fresh fruit and vegetables, with “natural” labels, obtained through laser marking.

This is only one of the many applications of CO2 lasers, a technology that demonstrates, again, to be a green process. In fact, producing a mark directly on the skin of produces results in reducing the consumption of materials such as paper and plastic and thus in a smaller environmental footprint of the packaging process. A CO2 laser let you engrave to engrave a lot of information: traceability codes, logo and brand of the producer, expiration dates. All this pieces of information were usually printed on traditional labels that were sticked on the surface of produces.

This laser labeling system is very advantageous for the whole packaging process and for the environment as well: a smaller energy consumption, the reduction of potentially polluting materials, a higher speed of execution. A perfect tool for all the manufacturers aiming at a greener production process.

But how can a CO2 laser engrave the surface of fresh fruit and vegetables?

Laser marking of food

Laser labeling of food is a special application of CO2 laser marking. In a previous article we have assessed the efficiency of laser marking on organic materials such as wood or leather. Even food can be marked without difficulty.

Broadly speaking, the process of laser marking relies on the high energy density delivered by a laser on the surface of a workpiece. It is that process that produces the desired marking on the surface.

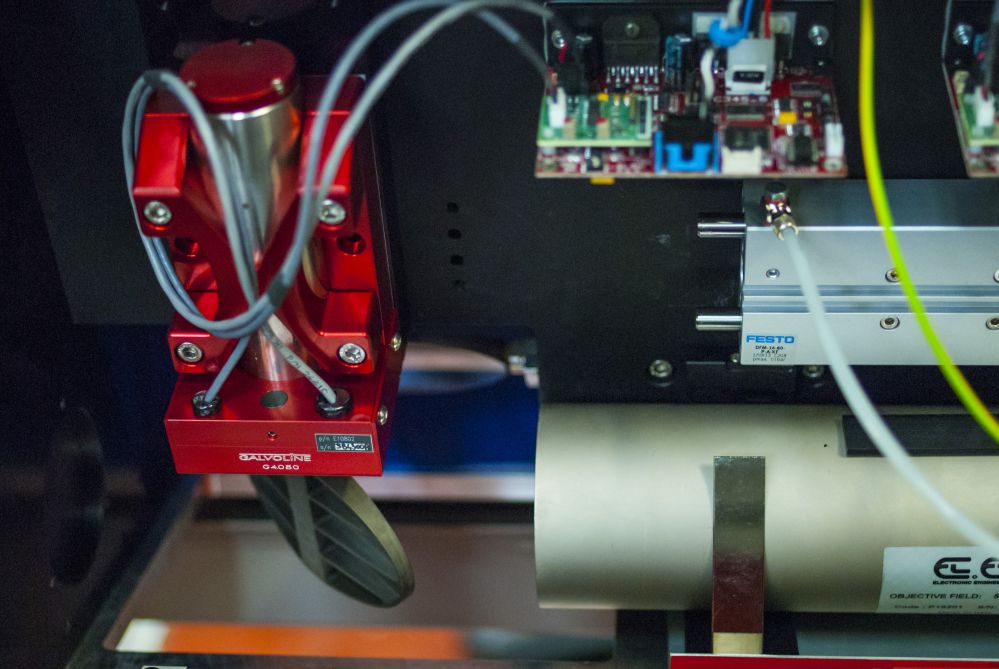

An ordinary laser marking system is composed of three parts: a scanning head, a low power CO2 laser source and a computer equipped with the control software.

The scanning head contains three components: two galvo motors with two beryllium mirrors mounted on them; one linear actuator that dynamically adapt the focal length of a lens. The goal of this device is to deflect the laser beam and keep it always focused on the surface of the workpiece. Thanks to the laser scanning head the laser beam can be delivered on the entire surface of the workpiece.

Both the CO2 laser source and the scanning head are controlled by a software that, fed with the correct parameters, achieves the marking process of the desired design. In this way it is possible to control the speed, the position and the power of the laser beam, making it possible to obtain all types of images, logos, codes and markings.

A laser marking system can be adapted to many situations and it can be integrated in existing lines without effort.

The process of labeling trough CO2 laser marking is applicable to any sort of fruits and vegetables. Nevertheless, the best results are obtained with fruit and vegetables having a wooden or thin skin e.g. tomatoes, apples, grapefruits, walnuts, chestnuts, coconuts, pumpkins etc. In this sector it is possible to mark pieces of information such as produce traceability codes, expiration dates, logos of the producer and other personalized information.

The benefits obtained through natural branding are manifold:

- Small amount of energy consumption: the CO2 laser systems employs very small amounts of energy to do the job, resulting in a reduction of costs.

- No consumption of plastic, paper or glue: in CO2 laser labeling of food, labels are directly engraved on the surface of the product. Therefore the environmental footprint can be reduced to a minimum.

- Cleanliness: with CO2 laser marking, the products don’t come into contact with chemical substances like glue. Hence the wholesomeness of the produce is enhanced.

- Higher productivity: the laser marking process is very fast. Although the processing speed depends on the complexity of the information that must be engraved, in most situations the processing time ranges from fraction of seconds, for simple codes to a few seconds, for complex geometries.

At this stage it should be clear why laser labeling of fresh produces is also known as natural branding. It should also be clear how laser labeling is suitable for producers of organic or biological produces and, in general, for all the companies interested in improving their environmental footprint.

A case study: marking traceability codes on apples

Let’s see now how a CO2 laser labeling system has been applied to a line of selection and sorting of fresh produces, in this case apples.

This system was composed by a laser scanning head, a low power CO2 laser source with a wavelength of 10.6 micrometers and a computer with the software that controlled the entire process. The marking system was designed for the integration in the existing machine and was engineered to achieve laser marking of apples on the fly.

That means that the system was able to determine the position and the speed of each apple passing on the moving belt, thus synchronizing the behaviour of the laser beam with the position of the apples on the belt.

The system proved to be extremely fast: it could mark 6 apples per seconds. As we said this speed it’s not fixed but depends on the complexity of the results that need to be achieved.

The energy consumption of this system was of the lowest: the laser source in this applications consumed only 0,3 kW. Although it was designed for apples, this configurations of a laser labeling system can be extended to any typology of fresh fruit and vegetables and seamlessly integrated in existing production lines.

A safe process that doesn’t affect the quality of produces

Laser labeling is a safe process. The marking only affects the most superficial layer of the skin of fresh produces; all the organoleptic properties of the food are respected. They are not modified in taste, color or smell. And the shelf life remains the same: some papers have also highlighted that laser marking never reduce the quality of produces.

The laser labeling of fresh products is an application yet to be explored. The possibilities are wide and let companies greatly improve their environmental footprint.