Modified atmosphere packaging, follows unique dynamics that you do not find in regular packaging supplies. It requires a precise regulation of parameters such as gas mixture and gas exchanges. It must take into account the fact that fresh products continue to exchange gases even after being put into the package. Laser technology is perfect tool to control those parameters through the manufacturing micro perforated packaging.

The domain of flexible packaging

Plastics polymers are used a lot in the food packaging industry, most successfully for fresh produce. Their versatility and resistance to chemical agents make them perfect for this type of application.

Their high capacity for transpiration makes them ideal for fresh produce. Every material, has its own natural traspirability that is its permeability to different types of gas molecules, particularly oxygen, carbon dioxide and water vapour.

This particular characteristic is fundamental for the conservation of fresh produce. The metabolic processes aren’t interrupted once the produce is picked. Processes such as cellular respiration and maturing, continue even after the produce has been packaged. If not appropriately counteracted, these processes can be responsible for a fast deterioration of the product. This is the reason why one of the biggest challenges of the fresh food industry is to slow down the metabolic processes that make the product unfit for consumption.

Packaging technology has found different solutions to circumvent the problem of produce deterioration. Disinfecting treatments, both chemical and mechanical or antifungal, go hand in hand with protective barriers such as plastic film.

Great progress has been made after the introduction of produce packaging in controlled atmosphere. This process takes advantage of the high transpirability of plastic film. The driving principle is to find the right balance between the gases within the packaging in order to counteract the deterioration process. Because every type of fresh produce has different metabolic processes going on, it is fundamental to choose the appropriate type of film that allows the best exchange of gas between the inside of the packaging and the outside.

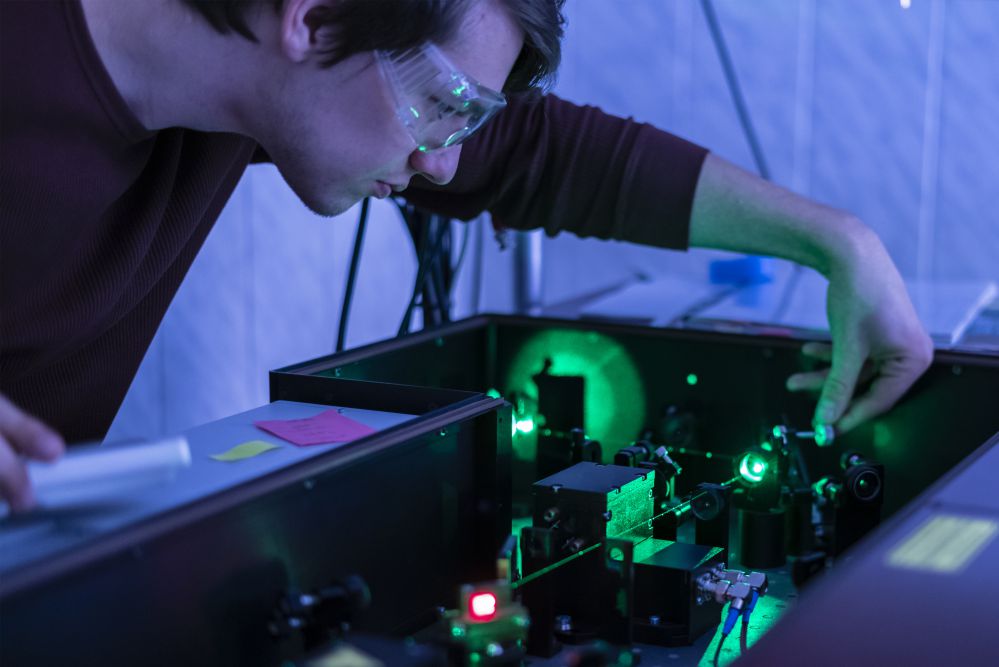

Unfortunately, many films don’t enable the right relationship between the gas entering and exiting the packaged product. What can be done, then? Laser microperforation can solve the problem. It makes it possible to make microscopic holes on the surface of the plastic film. Depending on the size of the perforations (that can range between 50 to 200 micrometers), it becomes possible to control the gases that go in and out and therefore maintain the right balance between gas and humidity within the packaging.

The advantage of this type of process is that it is easily integrable in a controlled atmosphere produce packaging plant. Let us imagine a company that deals with different types of produce. Each one needs to be packaged according its own specificities. The packaging has to be tailored to each product in order to have the right balance of gas inside the packaging. Laser technology allows for the optimisation of the entire production cycle. Each type of produce can be packaged without any change of machinery; a simple reprogramming of the laser control software is all that is needed.