CO2 lasers are one of the most widely employed technologies in manufacturing. The technology is so flexible and powerful that it is installed on a large number of industrial machines, used in a wide array of sectors. CO2 laser sources are well renowned for their resiliency: a machine based on this technology insures thousands of hours of high quality work.

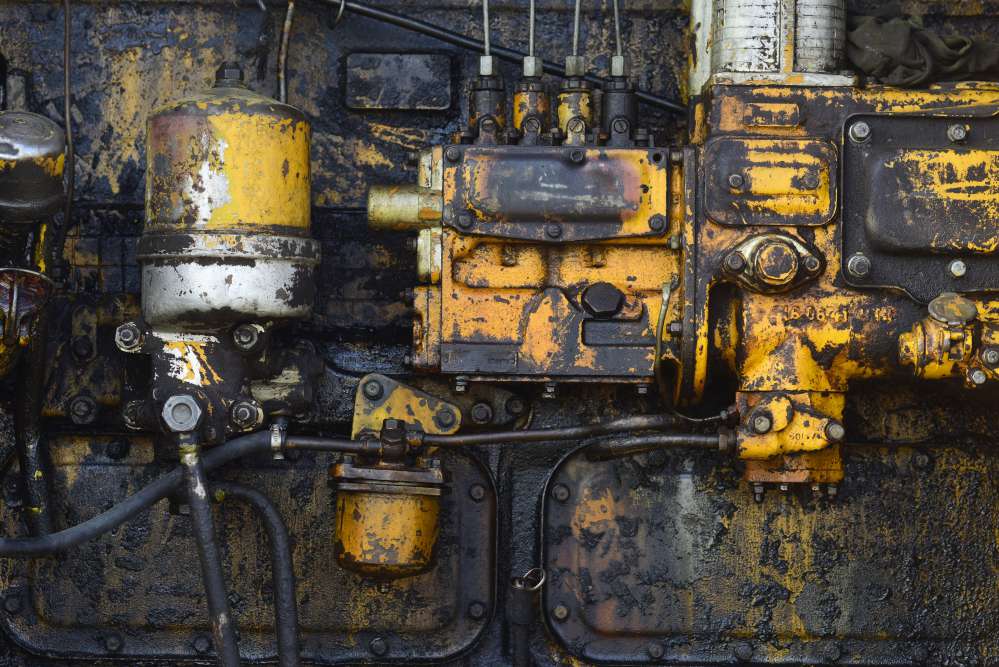

This type of laser still needs periodical maintenance work. Its weakness is a slow but inevitable loss of power.

Gas leaks, CO2 lasers’ weakness

Excessive gas leakage has consequences on the laser’s output. Its power will either decrease over time or be reduced drastically all of a sudden during operation. This phenomenon produces a reduction in the quality of operation: the laser beam becomes unstable and precision work is compromised. When that happens, laser maintenance is necessary.

Maintaining CO2 lasers

Maintenance can be done by the producer or by a company specialised in this sort of operations. Generally, maintenance work includes disassembling the machine and refilling the gas tube. Many specialised companies offer this type of service, which often also includes the cleaning and realignment of the optics and other components of the laser source.

These operations, even when carried out by professionals, do expose the laser source to potential infiltrations of dust and other microscopic foreign bodies. This sort of infiltrations could compromise the laser beam quality and, as a result, the good working conditions of the machine. Transporting the machine to the maintenance service facilities can also expose it to accidental damage.

It is important to bear in mind that every maintenance will cause a standstill of production that can last from a few days up to a few weeks.

The advantages of El.En’s Self-Refilling technology: Never Ending Power

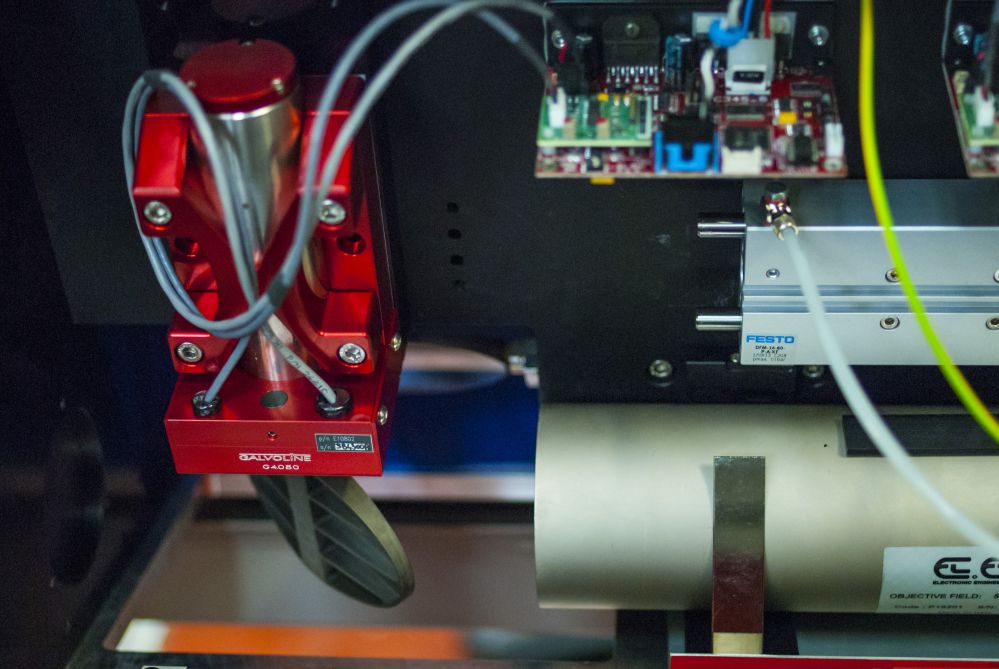

As a solution to the drawbacks of maintenance, El.En.’s research and development department has developed an innovative Self-Refilling technology. Thanks to Self-Refilling, gas-refilling operations can be carried out directly in-company.

The Self-Refilling system is based on disposable CO2 gas canisters. Every laser source has an in-built lid-protected slot for gas canisters. When it is time to refill the laser source, one needs to simply open the lid, take the empty canister out and put a new canister in. This way the laser source will maintain its max power and its operational standards will be preserved. Servicing operations can be carried out manually and without the laser source producer’s assistance.

The ability to independently refill a CO2 laser source brings about several advantages. Here are some:

- interruptions to production are reduced to a few minutes

- crucial parts of laser sources, such as the optics, stay sealed

- chances of infiltration of dust and foreign bodies are greatly reduced

- chances of damages from transportation are reduced

There are huge savings on resources and the laser source is always at max power and efficiency.

The Blade RF series of Self-Refilling CO2 laser sources are equipped with this innovative technology. These sources all have a compact design, come in multiple power options and can operate on a large variety of materials. Explore our range of products and discover the vast array of available applications.