Laser marking has become a standard in many industrial sectors. Its advantages are flexibility, speed, precision, the quality of the etched signs, eco-friendliness.

The vast majority of laser marking applications are aimed at identifying products and components. This role is traditionally played by labels of various types, printed or engraved and subsequently applied to products. Laser marking replaces the labels and allows information to be engraved directly on the surface of the product or component.

How laser marking process works

The laser marking process takes place through the interaction between the laser beam and the surface of a material. This interaction triggers an ablation process, through which a superficial layer of variable size is removed. The final result depends on which type of material is being marked and which type of laser is being used. The CO2 laser is the most used in laser marking processes because it can be applied to many materials.

What information can be laser marked

Laser technology makes it possible to engrave all kinds of information about a product. Some examples are:

- barcodes

- QR codes

- sequences of alphanumeric characters

- production lots and expiration dates

- copyright information

- manufacturer’s logos

- compliance logos

The advantages of laser labeling

Currently, there are three main ways to apply information on the surface of a product:

- Inkjet printing. It prints alphanumeric codes using a dot-matrix printer. This type of application is used on organic products that could be damaged by the laser’s heat. However in recent years it has been found out that laser can also be used successfully to label fruit, vegetables and other organic materials. Even if ink-jet printing guarantees a high level of productivity, it isn’t always long lasting since different materials retain the ink better than others, and the maintenance of the production line can be costly.

- Metal stamping. It prints signs by plastic deformation of the material’s surface. The imprinted marks are evident and can’t be counterfeited easily. It can be applied on metal labels that are then affixed to the different components, but it is not suitable for direct marking applications on the component itself. Metal stamping requires the use of a specific imprinting tools and dies, which have high maintenance costs. Also, changing the information to print is expensive because it requires changing the printing tool.

- Self-adhesive labels. Information is printed on a self-adhesive label which is then applied to the product. Labels are not very environmentally friendly because the back of the stickers are discarded.

Compared to these marking systems, the creation of labels by laser marking has undoubted advantages.

- Quality. Laser markings are perfectly defined and never fade, however much the product is subjected to intensive use. Laser technology suits well where preventing counterfeiting is necessary.

- Cost. While it is true that laser requires a greater initial investment than the other methods, it also has much lower maintenance and processing costs. Laser is advantageous when used in production processes that foster its strengths, that is favor high levels of customization, highly automated management of processes and perfection of the output.

- Flexibility. The printed information can be modified and updated very quickly without the need to adapt work tools or its ensuing costs. Tooling changes and machine preparation are reduced to practically nothing. Laser marking makes it possible to access a piece’s recessed areas that would remain inaccessible with conventional technologies.

- Respect for the environment. Laser labeling is more eco-friendly than traditional labeling since the consumption of plastic, ink and glue for labels is reduced considerably, as well as the costs associated with the disposal of unused sticker’s support.

- Efficiency. The information on the labels can be immediately digitally processed. It is therefore possible to increase the traceability of the processed pieces. Laser marking of labels can also be made on the fly.

Applications

There are many laser marking applications which range from the traditional ones like the marking of parts and components to the more advanced ones like the laser marking of food. There are many examples of applications in this latter area:

- engraving of codes on eggshells: this case study shows how laser marking can replace ink printing on eggshells

- marking of cold cuts and cheese wheel: cheese wheels and cured meat can be easily marked with laser. In this application laser marking replaces hot marking

- marking of fresh produce: in this application, laser marking is used to engrave information and logos directly on the surface of fruit and vegetables. In this case, laser marking replaces the self-adhesive labels

Other application examples include:

- Automotive: windshield engraving, identification of car components

- Gifts: product information

- Electronics: laser marking marking of silicon boards for integrated circuits

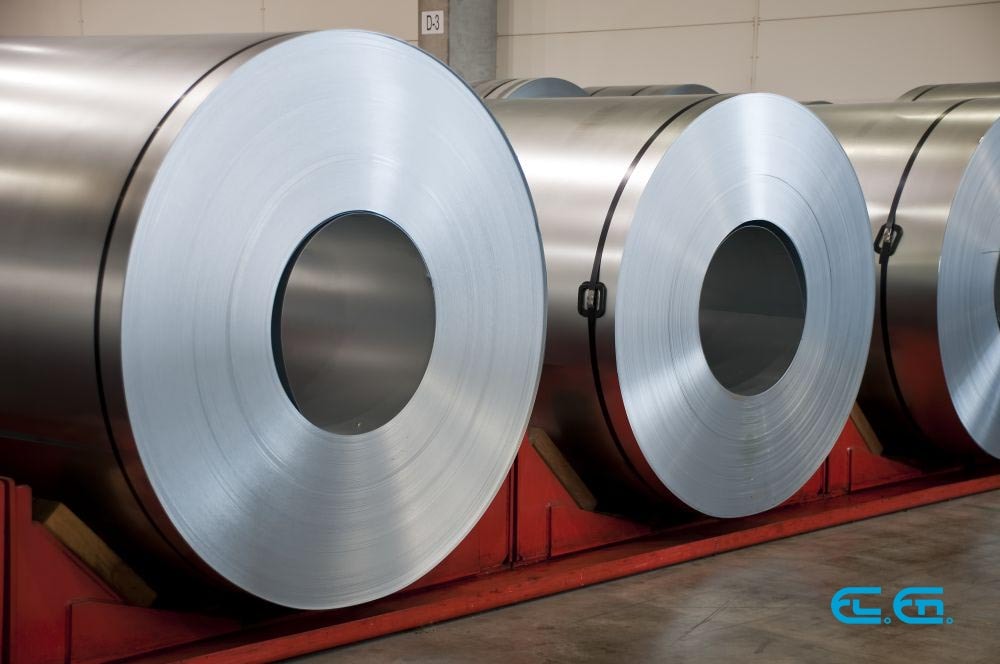

- Engineering: marking of construction components

What is your application?

You might be considering how laser marking could help you improve your business. Here at El.En., our team of experts will be happy to help you choose the right laser system for your needs. Our laser sources and our scanning systems are used all over the world and help thousands of companies create high quality products. Contact us to learn more.