Microperforation is a laser process that consists in creating micro holes on a sheet of raw material. Microperforation makes it possible to precisely choose the size, depth and quantity of holes per square centimeter. The flexibility of this technique makes it easy for the operator to change the processing characteristics according to the intended final use of the piece.

There are many examples of this processing technique from various sectors:

- the paper industry where microperforation is used to create security paper, i.e. paper products with special features to make counterfeiting very difficult

- the industry of fabrics and leathers, microperforation can be used to add decorative elements but also to improve the breathability of materials

- a similar application is in the automotive sector, where for example, microperforation is used in the finishing of leather for the internal lining of cars

- the packaging sector, microperforation is widely used. It is used to microperforate the plastic film used for packaging in modified atmosphere because the size and density of the holes can be adjusted with great precision

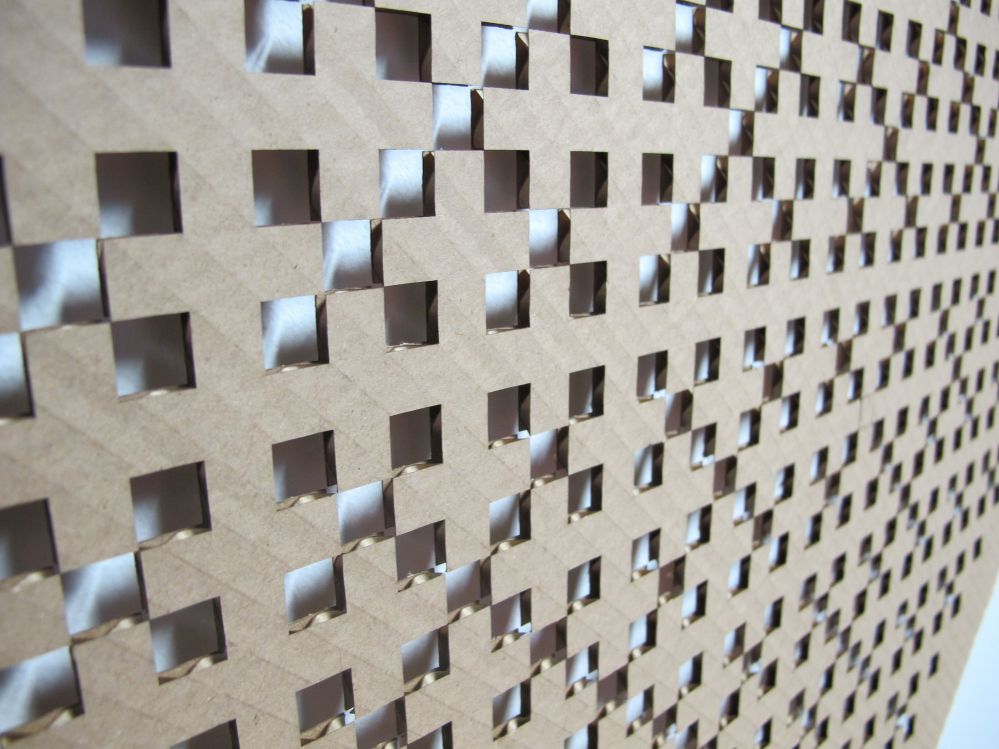

- Finally, a last example comes from the field of soundproofing. Sound absorbing tiles that perfectly muffle a specific type of frequency, are made with laser microperforation

The advantages of laser microperforation

Microperforation has several advantages over traditional applications. Here are two:

- Precision. Laser can perfectly calibrate the density, number, size and internal shape of the holes. Microperforation therefore allows you to create processes perfectly suited to the intended use of the product

- Flexibility. Different materials can be processed using the same laser source. CO2 laser sources are unbeatable for their flexibility of use

What materials can be processed with laser microperforation?

CO2 laser microperforation works best on flexible natural and synthetic materials. Some of them include:

- thermoplastic polymers, materials such as PMMA, polyethylene, PP and PET are among those most used in the packaging sector and suitable for this type of processing

- leather and hides

- fabrics made from natural and synthetic fiber

- paper and cardboard

Which laser source to choose to execute laser microperforation?

There are many factors to take into consideration when choosing the right laser source for microperforation.

One must consider the material being processed as well as the desired production outcome and process speed. Based on these elements, it is possible to establish the best wavelength and the power to use to get the job done.

Although finding the laser solution that best suits your needs may seem impossible, don’t worry, our experts have extensive experience on the field and will be able to help you find the laser system that’s right for you. Contact us for more information!