The manufacturing process of abrasive materials has always been a productive challenge. The main problem is that the abrasive power of these materials also exerts itself on the production tools themselves, damaging them over a short period of time.

This results in very high maintenance costs for the tools. In addition, the fact that using precision tools is difficult makes it impossible to carry out precise machining on these materials.

The introduction of laser technology was therefore a major innovation, as it made it easier and cheaper to manufacture abrasive tools and materials:

- Laser production processes are contactless. In laser processing, no mechanical forces are involved, unlike in traditional manufacturing processes. The interaction between the laser beam and the material produces a high energy density that removes a certain amount of material.

- Laser technology enables a high degree of control over the production process. What does that mean? It is possible to set up the laser parameters, down to the smallest detail, in order to minimise the difference between the desired result and the result obtained. In other words, you can create a material with characteristics that are perfectly suited to its intended use.

Diamond abrasives

A few decades ago, diamond abrasives joined the ranks of traditional abrasives. These tools exploit diamond’s exceptional hardness and thermal conductivity to achieve excellent abrasive performance.

Diamond is one of the hardest materials known to man. It also has excellent strength, good wear resistance and a low friction coefficient.

Diamond tools can be used in a wide range of applications:

- geological prospecting

- stone processing

- construction

- woodworking

- tooling

- ceramic processing

Diamond tools can be manufactured in various ways. Generally, synthetic diamonds are used, or diamonds judged to be of unsuitable quality for jewellery making.

To make tools, diamonds are combined with another bonding material so that, for example, tools can be made from metal, resin, ceramics, etc.

They can also be used for a wide range of purposes, including all traditional mechanical operations. These include cutting, drilling and, among other things, abrasive tools.

The manufacturing process for diamond abrasive tools comes with the same difficulties encountered in the production of conventional abrasive tools. However, it also has an added difficulty: the hardness of the diamond subjects the production equipment to even greater stress.

Here too, the CO2 laser can be an advantageous solution.

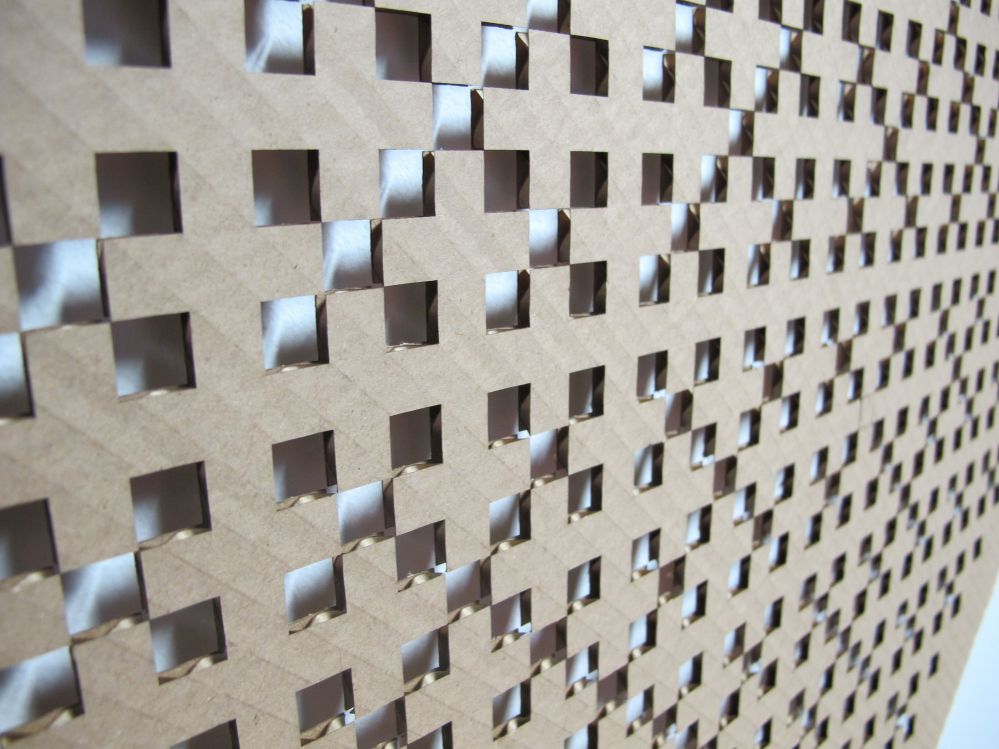

Diamond abrasives can be subjected to laser ablation processes using a continuous wave laser. This technique can create textures and other passive layer characteristics that enhance the performance of the material.

The process is especially effective on resin bonded abrasive materials. Resins and plastics in general absorb CO2 laser radiation very well and, therefore work very effectively for laser ablation processes.

A new application for the CO2 laser

Diamond is one of the hardest materials in existence, which makes the efficient production of these tools difficult and limits their widespread use. On the other hand, however, diamond abrasive tools offer enormous advantages and are crucial in certain applications. The introduction of laser machining processes has made their production more efficient and cost-effective, paving the way for their widespread use. Research in the field is still ongoing, bringing with it other possible applications in the future.

El.En. has been producing CO2 lasers for various industrial sectors for over 35 years. Experimentation, research and development in the field of lasers applied to materials is in our DNA. If you are thinking of making an application of this type, contact us and we will be happy to study the ideal solution for your needs.