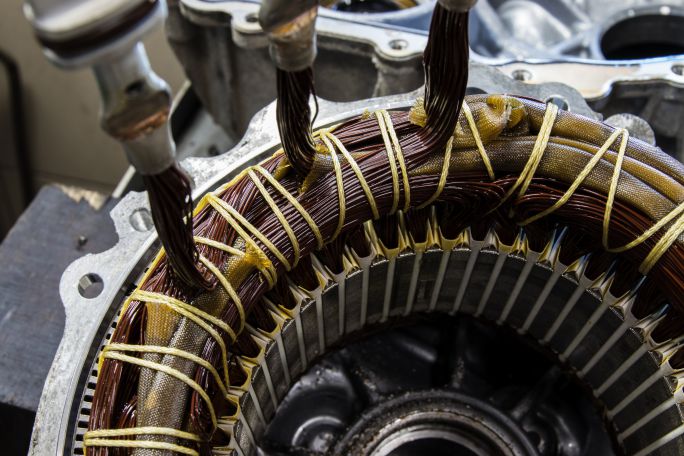

Abrasives, part of a family of materials characterised by their great hardness, are used for processes such as polishing or the sanding of surfaces. They are available in a wide variety of shapes and types and lend themselves to a multitude of processes.

These materials can be moulded into a large number of shapes: discs, brushes, wheels, cutters, grinding wheels. However, traditional abrasive processing methods have limitations that can be overcome with laser processing.

In this article we will look at the 6 advantages of using laser technology in the manufacturing process of abrasive products.

1. Laser is a non-contact process

The main problem in the manufacturing of abrasives is that the abrasive action is also exerted on the tool itself. Let us take flexible abrasives as an example. In this category of abrasives, the abrasive substance is sprinkled on a backing, which is normally made of paper or a polymer material. In order to obtain the desired shapes, such as a rotating disc or wheel, tools such as dies are used, i.e. a mechanical method that uses contact between parts to separate an element from the die into the desired shape.

Operations such as die cutting of abrasive materials, however, have a drawback. The abrasive action is also exerted on the cutting tools. Blades, dies and cutters quickly get worn out and must be replaced frequently to maintain high machining quality. This increases machining costs, which consequently increases the cost of the final product.

Laser cutting of abrasive materials overcomes this disadvantage. It is characterised by a total absence of contact. The laser beam interacts remotely with the surface of the material in a non-mechanical process that avoids the problem of continuous wear of the machining tools.

2. Laser is a versatile tool

A major disadvantage of traditional machining methods is also their lack of flexibility. For example, a die made to create a specific shape can only be used to create that specific shape. To make differently shaped parts, it is necessary to create new diecuts, provided that the investment required to create them is justified by a profitable return.

Similarly, only one machining operation can be performed with traditional machining tools. A die-cutting tool can only perform one machining operation. A cutting tool can only perform cutting. To perform different machining operations, one must change the machining tool. If a manufacturer wanted to apply information to an abrasive disc such as grit size or a serial number, he would have to insert the part into a dedicated machine, such as a printing machine.

Laser systems, on the other hand, allow several machining operations to be performed in a single session. With the same system, flexible discs can be cut from a die, cuts and perforations can be made and surface information on a material can be added through laser marking. In addition, the use of lasers allows the shape or size of the piece being manufactured to be changed in real time, without any additional aids. It is precisely its high flexibility that makes the laser the trump card for this type of application.

Laser offers a true change in the very way production is understood. It gives manufacturers the possibility of enormously expanding their commercial offerings. It becomes possible to create prototypes, just-in-time production, or series of small parts for high-value customers.

3. Laser is a precise tool

Abrasives are used in many different industries. Each of them requires specific processes, and, therefore, abrasive tools that are shaped differently. This means that there are more or less specialised tools: from simple sandpaper, sold in rolls and used by carpenters and craftsmen, to customised rotating discs for high-precision machining.

However, mechanical machining tools have a tolerance limit beyond which they cannot go. The size of the machining tools, their design, and the need to avoid unwanted contact limit the complexity of the machining that can be performed.

Laser, on the other hand, allows very tight tolerances. Since there is no contact between the parts, the tool can follow intricate cutting paths, create microscopic perforations and special shapes, make surface cuts and other machining operations that would be impossible with mechanical cutting tools.

4. Laser reduces machining waste

With traditional machining tools, processing is performed by the mechanical removal of material. The process tends to produce machining waste, dust and other residues that must be managed in some way, with a variable economic and environmental cost.

Laser machining processes, on the other hand, tend not to produce waste. Material removal occurs through sublimation. The very high energy density produced by the laser on the surface allows the temperature of the material to rise, instantly vaporising it as a result of a transformation of the material state.

5. Laser respects materials

Mechanical machining processes present a risk of damage to products due to accidental contact or excessive mechanical contact. Any deformation lowers the quality of the final product.

In laser processing, there is no risk of damage from mechanical contact. Laser processing respects all materials, even the most delicate ones. They guarantee a higher quality of the finished part and are therefore ideal for the sectors in which the degree of error must be kept down to a minimum.

6. Laser is an environmentally friendly process

Laser processing offers high energy efficiency. All things being equal, laser performs the processing with much lower energy expenditure than mechanical processing. This, combined with the absence of waste, makes the laser one of the most environmentally friendly processing tools available to manufacturers.

Contact us

Laser is a cost-effective tool for the manufacturing of abrasive materials. Because the possible applications are numerous, seeking the advice of an expert can help you find the most suitable processing system for your application. El.En. CO2 laser systems are ideal for the manufacturing of abrasive materials. Contact us for more information.