The synthetic leather market has seen exponential growth in recent years. Natural leather is becoming an increasingly scarce commodity, both for economic and environmental reasons. On the one hand, the need for finished products at ever lower prices limits the use of expensive raw materials, and on the other, animal and environmental issues are driving companies to choose eco-friendly solutions.

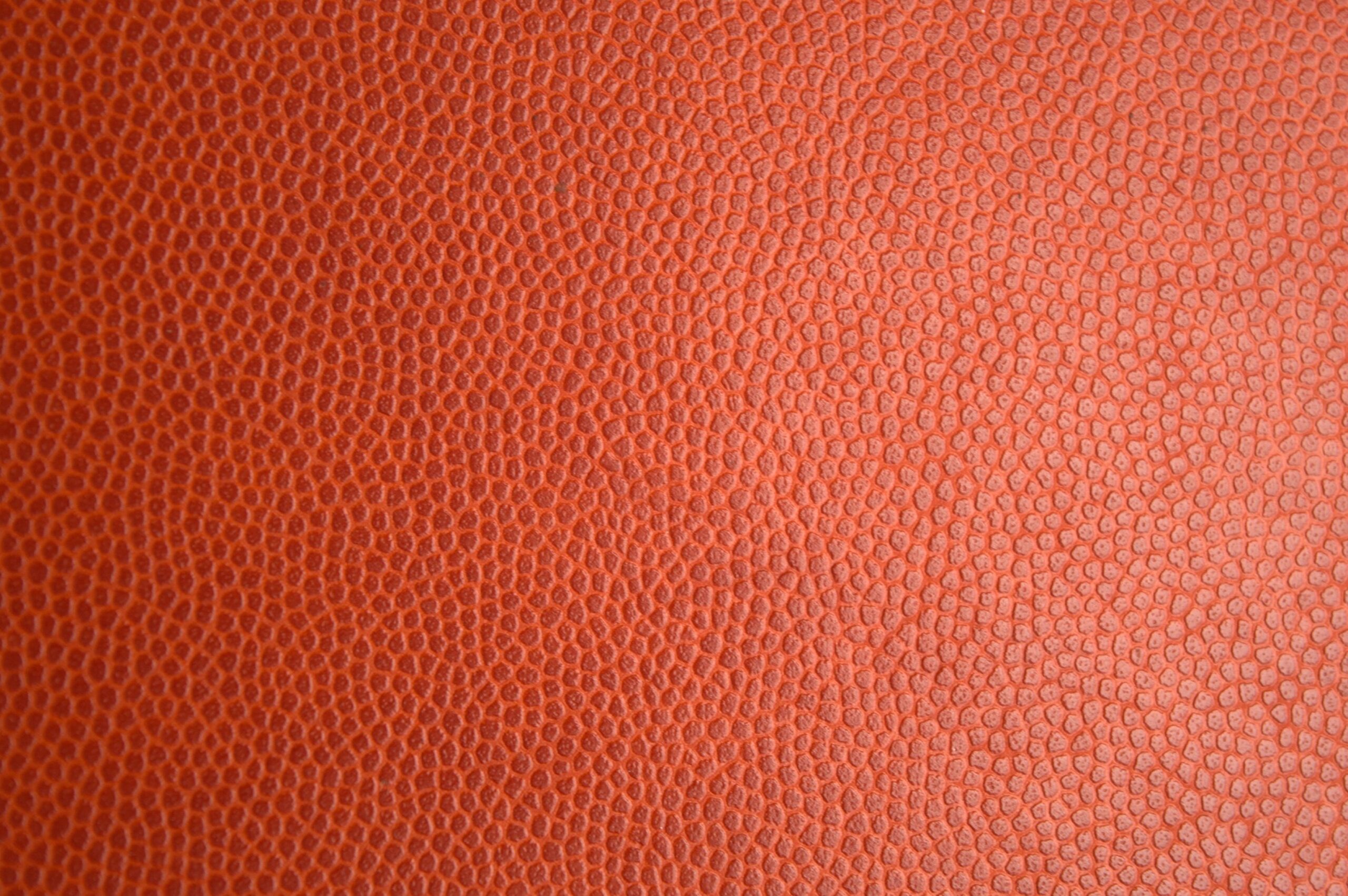

Synthetic leather is very similar to natural leather from both a technological and sensory point of view. Unlike natural leather, it is not a breathable material. It also needs a base layer, often made of cotton or other natural fibres.

The advantages of synthetic leather over hide are many:

- production costs are very low

- the production batches are very uniform

- textures and effects that do not exist in nature can be produced

- it is easier to cut and sew

Far from being a less noble alternative to the original material, synthetic leather is a practical and modern material. It can be successfully used everywhere traditional leather was, with the same aesthetic and technical results.

The composition of artificial leather

Synthetic leather is made up of two layers, an upper one that imitates leather and a lower one acting as a base.

The upper layer is composed of a synthetic polymer. The most used materials are PVC (Polyvinyl chloride) and Polyurethane (PU). The two materials differ slightly. Most synthetic leather is made of PVC due to its low cost and greater resistance. Polyurethane, a costlier material, is less frequently used even though it feels more like real leather to the touch.

The artificial leather base is in fabric which can be made from synthetic fibres, natural ones (usually cotton) or even natural-synthetic blends.

The role of the fabric base is very important. The mechanical properties of synthetic leather rely on the strength of its base. The lifespan of synthetic leather is in direct correlation to the one of the fabric base.

Can you laser engrave faux leather?

The answer is yes, you can. Due to its thermoplastic polymer composition, synthetic leather lends itself very well to laser processing, particularly with CO2 lasers. The interactions between materials such as PVC and Polyurethane and the laser beam achieve high energy efficiency, ensuring optimal results.

Laser marking and engraving

The marking and engraving processes are very similar. In both cases, the laser beam acts on the surface layers. The laser energy activates alterations which, depending on the intensity, can be more or less deep or radical.

In marking processes, the applied energy density is very low. The material’s transformations stay at a superficial level and are more aesthetic in nature.

In laser engraving, the applied energy density is higher and reaches deeper layers of the material. It therefore undergoes substantial chemical transformations. The marking is more visible and contrasted. The end result can have a tactile finish and even a natural texture.

Laser parameters

The system must be set according to certain parameters to achieve the desired laser marking or engraving effects. There is no universal rule one can follow to set the system. The correct parameters depend on factors such as:

- the type of material used: polyvinyl chloride and polyurethane absorb energy differently. So the settings must be regulated differently.

- the colour of the leather: light coloured leather is more reflective than a darker one. Dark leather therefore absorbs the laser beam better, resulting in greater energy efficiency and faster processing.

A correct laser setting will aim to achieve the correct energy density in order to obtain a clearly visible mark without damaging the material.

Laser Engraving Systems

Leather marking/engraving is one of the applications of galvo scanning. This category includes all processes in which the laser source is used in combination with a scanning head.

The scanning head distributes the laser beam produced by the source on the material’s surface.

Laser sources and scanning heads are available in different models depending on production needs. In order to make the right choice, it is necessary to know your particular manufacturing characteristics. Send us information about your production plant and requirements and we will be happy to design a tailor made leather laser marking/engraving system to suit your needs.