Laser cutting of wood-based products is one of the most important applications of CO2 lasers. Today, laser is a powerful, flexible and reliable tool: it made it possible to overcome the limits imposed by the traditional methods of machining wood based materials.

The advantages of laser production are many. Here’s a few:

- it tremendously speeded up operations such as cutting, drilling or marking on various materials

- it allowed to extend the use of materials such as engineered wood products for the production of parts and components

- it allowed operations that couldn’t be achieved with traditional, mechanical, applications, due to the limits of either the material and the machines

It’s no coincidence that one of the first commercial applications of CO2 lasers was the cutting of plywood die boards for the packaging industry. This sector in particular has really benefitted from the advent of laser-based production methods. The reason is that CO2 lasers are perfect for machining wood, paper, cardboard and similar products, largely used by the packaging industry. CO2 laser cutting opened up a new range of possibilities for this industry.

But how does the CO2 laser cutting process work?

CO2 laser cutting, a precision technology

The laser cutting process in itself does not involve any mechanical force. It relies upon the physical and chemical processes that take place when a focused laser beam hits the surface of a material.

A high intensity beam of light is generated by a laser source, like one of our BLADE RF Self Refilling family. This laser beam is then reflected by a system of mirrors, until it passes through a lens which focuses the beam down to a small spot onto the surface.

This means that, in a single spot a fraction of a millimeter wide, is concentrated all the energy generated by the laser. The spot thus reachers a great energy density which causes the immediate sublimation of the material surface touched by the laser. In this way the desired cut is produced.

Despite the highest energies involved in this operation, laser cutting of wood is a very safe process. The entire operation is controlled by a computer, resulting in great accuracy. The cutting kerf is very narrow and precise and no damage is possible, provided that the laser is properly set.

The cuts obtained in such manner have some unquestionable qualities:

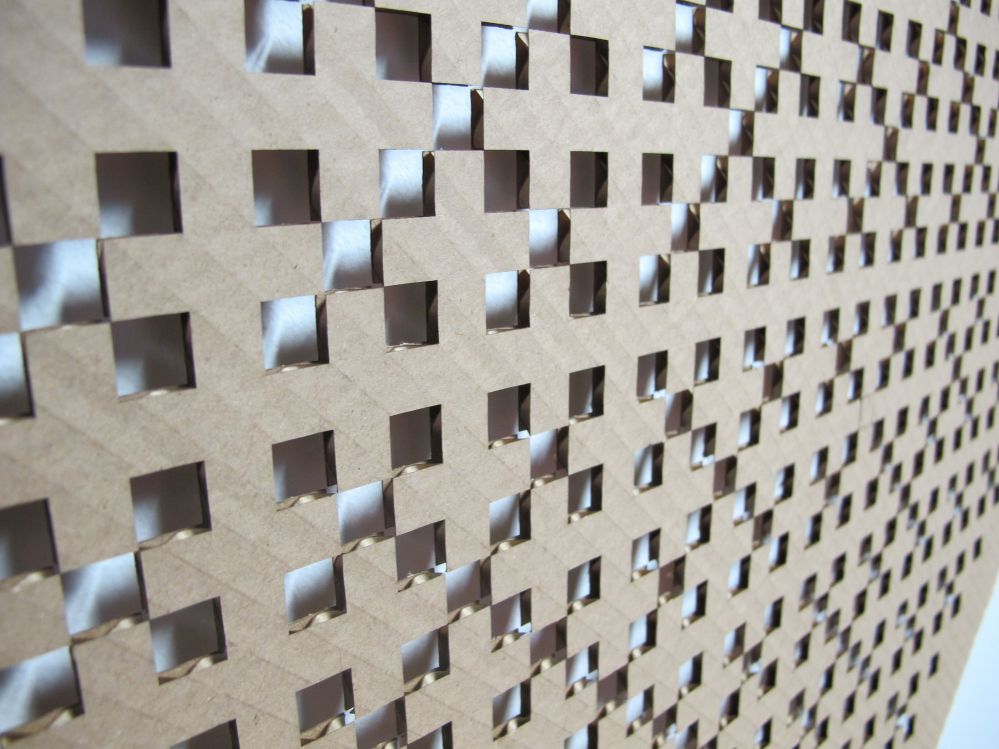

precision: the CO2 laser provides accurate cuts. The energy is focused precisely on the spot indicated by a software. Since the dimensions of this point are very small, working tolerances are very tight, allowing very complex profiling paths

smooth edges: the edges obtained from CO2 laser cutting don’t need further finish because they all have a polished appearance

Reduced costs: the laser cutting of wood results in the absence of any sawdust, shavings or other leftovers. This, combined with the lack of blades or other mechanical tools, create a very quiet working environment

Laser cutting of wood can be achieved on different types of woods. The results can vary a lot, depending on parameters such as the type of wood, its density and resin content and, of course, the thickness of the panel that is going to be cut.

Laser and MDF: an example of success in the industry of packaging

The best results of CO2 laser cutting on wooden products are achieved on the so called engineered woods. Those derivatives of wood include products such as plywoods, laminated woods and medium-density fibreboard or MDF.

Not too long ago, the operations that could be achieved on such materials were scarce, due to intrinsic properties of them. All engineered wood are composite materials, made from fibers of chips of wood pressed together. This features made them unsuitable for accurate machining operations, especially at a small scale. That’s why they’ve long been overlooked as engineering material.

CO2 laser cutting made those materials suitable for a new set of applications. An example of this can be seen in the packaging industry.

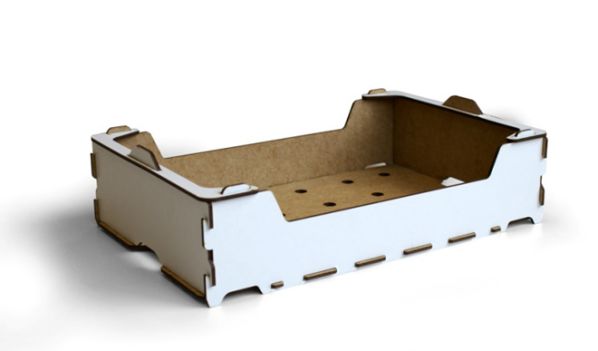

The construction of packaging products is a very challenging business. A good packaging has to be tough, light and attractive for the customers. But how to achieve all those contrasting needs? Thanks to CO2 laser cutting, the packaging industry introduced new materials for the creation and design of packaging. This is the case of boxes, crates and cases made from laser cut MDF panels.

MDF provides the same toughness and performance of solid wood but at a lower cost. Those characteristic make MDF a perfect material for the design and engineering of packaging products like boxes, crates and cases of various kind. A CO2 laser is able to easily cut the panel in MDF in all desired shapes and dimensions. It is possible, for instance, to produce the various components to assemble boxes and crates. In this way it becomes easier to create containers of every kind and dimensions, that can be used to protect delicate products like fruit from the risks of damage during shipping and transportation.

This is only one example of the many possible applications of CO2 laser cutting for wood. The introduction of such a technology affected many industrial sectors anche the packaging industry is only one of them.

It might also interest you: CO2 Laser: a new technology for the fabrication of corrugated fiberboard and cardboard