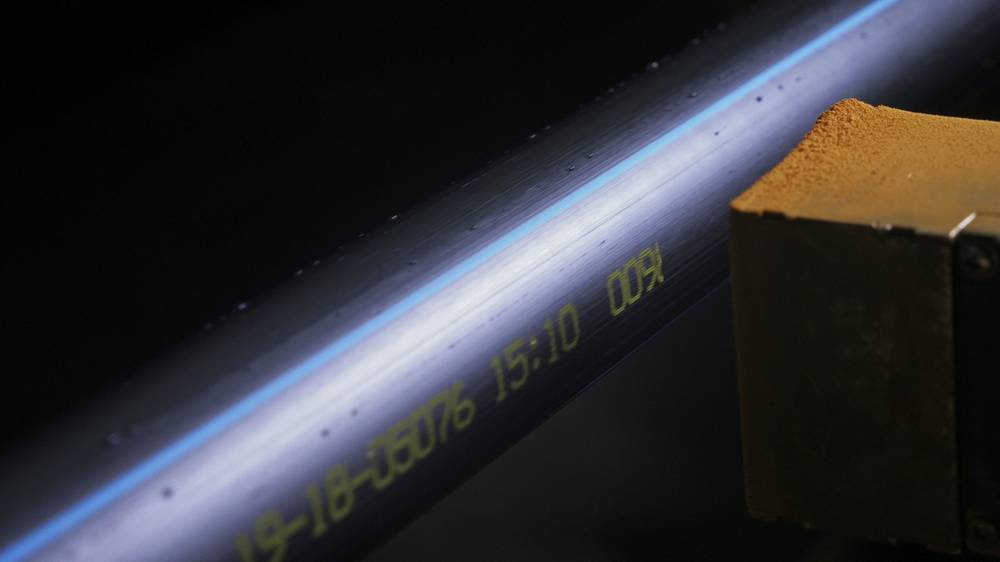

Laser marking is one of the most widely used laser processes in the industrial sector. It is typically used to apply information to packaging: expiry dates, traceability codes, production batches, logos and other graphics. The fundamental advantages of laser marking over traditional methods are the very high processing speeds and the high levels of precision that can be achieved.

But the advantages don’t stop there. Laser technology not only allows manufacturers to increase processing efficiency parameters, but also to perform types of processing that would be impossible to do with traditional methods.

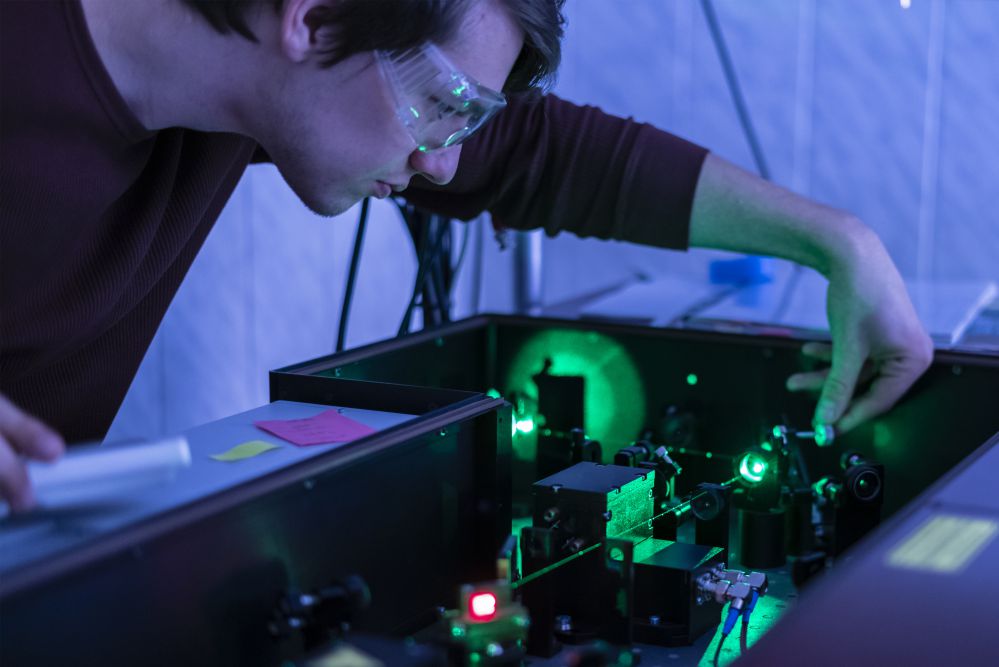

How does laser marking work?

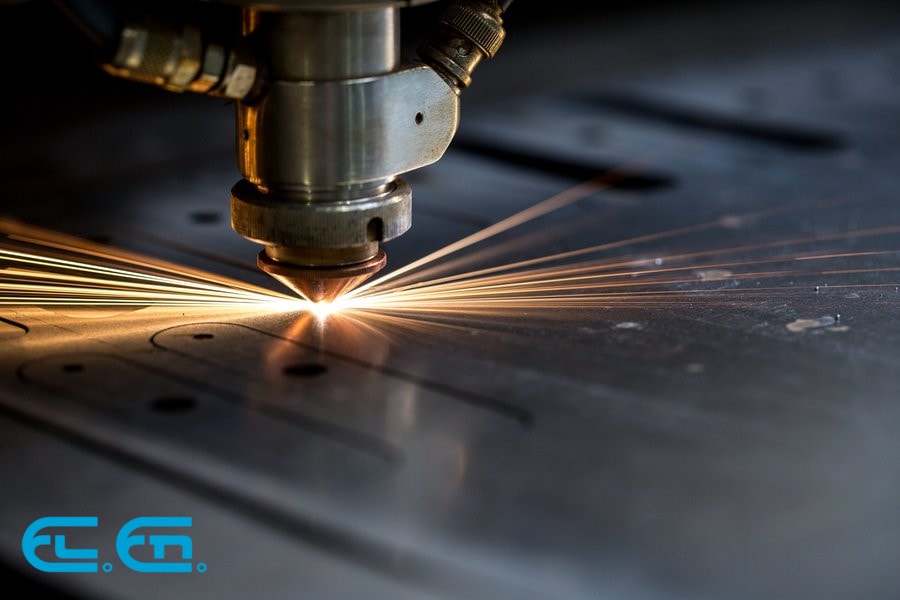

Laser marking is a processing technique in which a laser is used to produce an engraving on the surface of a product. As with all laser-based processes, this technique exploits the laser’s ability to concentrate large amounts of energy on one spot with a diameter of a tenth of a millimetre. At the site where the laser touches the material, very high energy densities are reached, which cause the temperature to rise within a few seconds, triggering physical and chemical transformations.

A key feature of laser processing is the high degree of control. It is possible to decide with great precision how deep the laser’s action should go. With laser marking, the mark is only produced superficially, on a layer that goes from a few microns to one or two millimetres. Past this depth, one no longer speaks of laser marking but of laser engraving. The two processes, although similar, differ in the depth of the laser marking which in turn changes its perception. Laser engraving creates marks that are more visible and perceptible to the touch. In laser engraving, the mark is visible but not very perceptible to the touch.

Laser marking and packaging

In all laser processing, the type of power used depends on two factors: the material one wants to process and the speed one wants to reach. As you may already know, every laser emits a beam of polarised light at a defined wavelength. Some materials absorb certain wavelengths well but not others. In the packaging sector, the CO2 laser is the one that gives the best results. Its 10.6 micrometer wavelength belongs to the far infrared region which is very well absorbed by the organic materials most frequently used for packaging (e.i: paper, cardboard, thermoplastic polymers, glass).

Advantages of laser marking

Traditionally, the following methods are used to mark information on packaging:

- inkjet printing

- thermal transfer printing

- stamping

- hot stamping

- mechanical engraving

These techniques are always based on contact between the tool and the workpiece. Compared to them, the laser has several advantages:

- reduced cost: the information is engraved directly on the product, which eliminates the need for any other material, such as ink and labels

- indelibility: it is resistant to wear, solvents, scratches, light and counterfeiting attempts.

- automation: the process is fully automatable.

- flexibility: laser marking can imprint any type of information, however complex.

- contact-free: materials are not subjected to mechanical stress.

Materials and laser marking

As mentioned above, the characteristics of the material used influence the specific characteristics of the marking operation.

Paper and cardboard packaging

Paper and cardboard are made from cellulose, a material of organic origin produced through wood processing. The laser acts on the paper by vaporising a thin layer of material. The resulting mark has the same light colour as the material and may therefore offer little contrast. The contrast can be increased by adding a dark-coloured overlay. In this case the laser only removes the coloured surface layer to reveal the light part underneath. The contrast between the white of the paper and the darker colour of the surrounding layer creates a very legible mark.

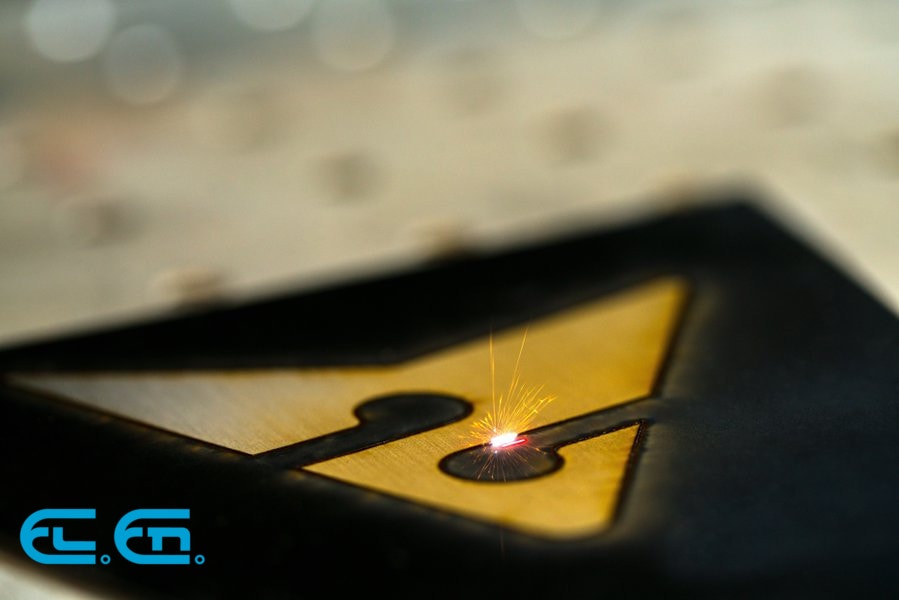

Laser marking on plastics

Plastic is a synthetic organic product based on carbon-based polymers. On certain types of plastic, the CO2 laser is very efficient and gives optimum results. The plastics that are best suited for laser marking are those most commonly used in the packaging industry, such as polyethylene, PET or polypropylene. Polypropylene is also suitable for laser cutting.

Laser marking on plastics is carried out by chemical transformation (the laser breaks polymer chains). The fact that the light affects the mark differently to the surrounding material makes it quite visible. Depending on the additives applied to the plastic, different levels of contrast can be achieved.

Laser marking on glass

Laser marking can also work with glass. Marking on glass is carried out through the physical transformation of the material. Glass is a very fragile and inflexible material that traps micro-bubbles of air inside itself. When the laser strikes the surface of the material, the air bubbles expand due to the heat, creating micro-fractures. This changes the transparency of the material and creates the mark.

Beyond packaging

In some cases, laser marking can eliminate packaging. In recent years, laser marking on food has become a well-established technique. It is mainly used on produce or cured meat and cheese but can be used on any compatible product. In this application, the marking is done directly on the surface of the product. A layer, a few microns deep, is removed from the surface. The laser beam does not penetrate into the product so its freshness is preserved. Several studies have shown that laser marking does not affect the quality of the product in any way. Food distributors rely on it to save on tons of packaging materials each year, including self-adhesive labels.

Equipment for laser marking in packaging

The technical requirements for a laser marking system are a CO2 laser source, which produces the beam, a scanning head, which moves the beam over a surface, and a software controller, which coordinates the system.

The laser source

In the El.En. catalogue we have laser sources that range from 60W to 1200W of power. Greater power corresponds to greater energy per unit area, which can be translated into greater execution speed. Our catalogue has a selection of laser sources optimised for certain packaging materials. BLADE RF177G and BLADE RF333P with their two different wavelengths of 9.3 um and 10.2 um are perfect for the materials used in the packaging industry and in kiss cutting for adhesive labels.

Our Never Ending Power sources use Self-Refilling technology that potentially makes the laser’s life endless. This involves the addition of a consumable, the gas cartridge, which contains the propagation medium and can be easily replaced when it runs out. In this way, sources can maintain their performance over time. Unlike sealed lasers, this eliminates the time-consuming and costly refurbishment process.

The scanning head

Applications such as marking are called galvo laser scanning because they use galvanometric mirrors to move the laser beam across the surface.

The main feature of our scanning heads is that they have a z-dynamic motor, which allows the focus to be adjusted in height and thus maintain constant parameters on the work area.

The digital controller

The CO2 laser source and the scanning head need software to coordinate their movements in order to perform the required machining. Our heads also include this control system, which can be easily integrated with common operating systems.

Contact El.En.

Laser marking is one of our areas of expertise. Our engineers have worked on dozens of laser marking application projects in this field. If you work in packaging and are interested in a laser solution, contact us and we will be happy to find the best solution for your needs.